| Model | YGL-120 | YGL-250 | YGL-350 | YGL-500 | YGL-700 | YGL-1000 | YGL-1200 |

|---|---|---|---|---|---|---|---|

| -10 | -20 | -30 | -40 | -60 | -80 | -100 | |

| Thermal Capacity(KW) | 120 | 250 | 350 | 500 | 700 | 930 | 1200 |

| Thermal Efficient(%) | ≧68 | ≧68 | ≧68 | ≧73 | ≧73 | ≧73 | ≧73 |

| Max. operating pressure(Mpa) | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Max.working temperature(℃) | 320 | 320 | 320 | 320 | 320 | 320 | 320 |

| Oil capacity in the heater (m3) | 0.12 | 0.2 | 0.3 | 0.4 | 0.6 | 0.9 | 1.1 |

| Circulated oil capacity(m3/h) | 20 | 32 | 40 | 60 | 60 | 80 | 100 |

| Caliber of the Pipe Connected (DN) | 50 | 50 | 80 | 100 | 100 | 125 | 125 |

| Installed Capacity(KW) | 10 | 11 | 15 | 24 | 24 | 38 | 38 |

| Profile Dimension(m) L*W*H | 1.4 | 1.4 | 1.6 | 1.9 | 1.9 | 2.3 | 2.3 |

| 1.4 | 1.4 | 1.6 | 1.9 | 1.9 | 2.3 | 2.3 | |

| 2.5 | 2.7 | 3.2 | 3.9 | 4.2 | 5.6 | 5.7 | |

| Diameter of Chimney(mm) | 250 | 250 | 300 | 350 | 400 | 500 | 500 |

| Flow/lift(m3) | 20/40 | 32/32 | 40/40 | 60/40 | 60/40 | 80/55 | 100/55 |

| Circulating pump (KW) | 4 | 5.5 | 7.5 | 15 | 15 | 22 | 22 |

| Boiler Total weight(Tons) | 3.8 | 4.2 | 4.4 | 4.6 | 5.5 | 7.1 | 7.4 |

| Model | YLL-500S | YLL-700S | YLL-1000S | YLL-1200S | YLL-1400S | YLL-1900S |

|---|---|---|---|---|---|---|

| Thermal Capacity(KW) | 500 | 700 | 1000 | 1200 | 1400 | 1900 |

| Max.working temperature(℃) | 320 | 320 | 320 | 320 | 320 | 320 |

| Max. operating pressure(Mpa) | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Thermal Efficient(%) | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 |

| Expension Tank (m³) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 4 |

| Storage Tank | 4 | 4 | 4 | 4 | 4 | 6 |

| Profile Dimension(m) L*W*H | 4.47*1.8*4.15 | 4.7*1.8*4.15 | 4.7*1.8*4.47 | 1.8*2.12*5.37 | 4.8*2.12*5.67 | 5.0*2.32*5.68 |

| Boiler Total weight(Tons) | 15 | 15.5 | 16 | 17.5 | 18.5 | 23 |

Plate and tube automatic welding

Mainly used for tube-tube sheet all-position welding, 100% pass rate, beautiful appearance, high welding strength, and prolong the service life of the smoke tube.

Automatic plasma cutting machine

It is mainly used for the unloading of large quantities of components of various geometric shapes. It can accommodate multiple steel plate unloading at the same time. It has automatic scribing, positioning, tracking, and correction functions, which ensures the accurate geometric dimensions and good finish of the unloading.

Universal plate rolling machine

It adopts advanced forming technology and synchronous tracking at the same time. It is mainly used for sheet coils and press forming under 30 thickness.

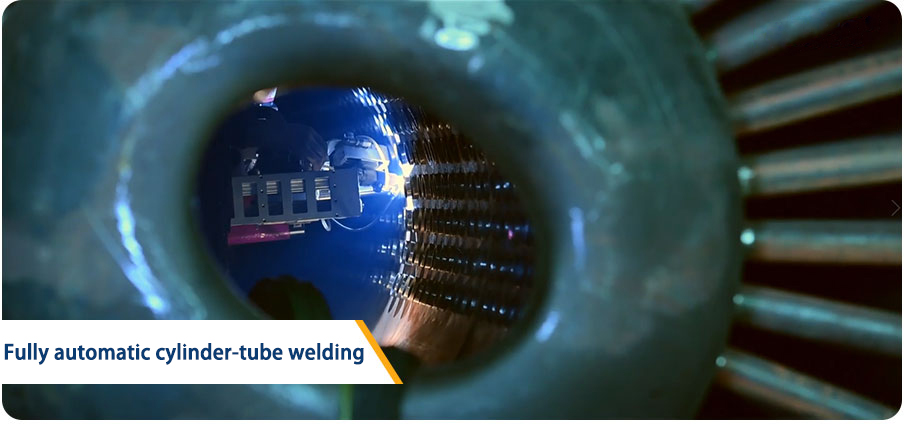

Fully automatic cylinder-tube welding

Multiple welding operation systems, positioners, control centers, and multiple integrated control methods to achieve automatic argon arc welding, automatic submerged arc welding and all mass production accessories (including flanges, etc.) on all cylinders Automatic welding in the machine. Welder imported from Germany.